Robotics Mining Competition. The UA team is the most decorated in the contest’s six-year history.

In the six years since NASA began hosting its Robotics Mining Competition, The University of Alabama Astrobotics team has emerged as the competition’s most successful team.

This past May, the team won the top prize at the contest held at the Kennedy Space Center in Florida. The team also won first place in 2012, making them the only team in the competition’s history to finish in first place more than once.

Overall, the UA team is the competition’s most decorated team, placing second in 2014 and third in 2013.

“The 2015 NASA RMC National Championship cements Alabama Astrobotics as the top robotic space mining program in the country,” said Dr. Kenneth Ricks, UA associate professor of electrical and computer engineering and team adviser. “This consistent level of excellence is unmatched and stands testament to the hard work and dedication of our students.”

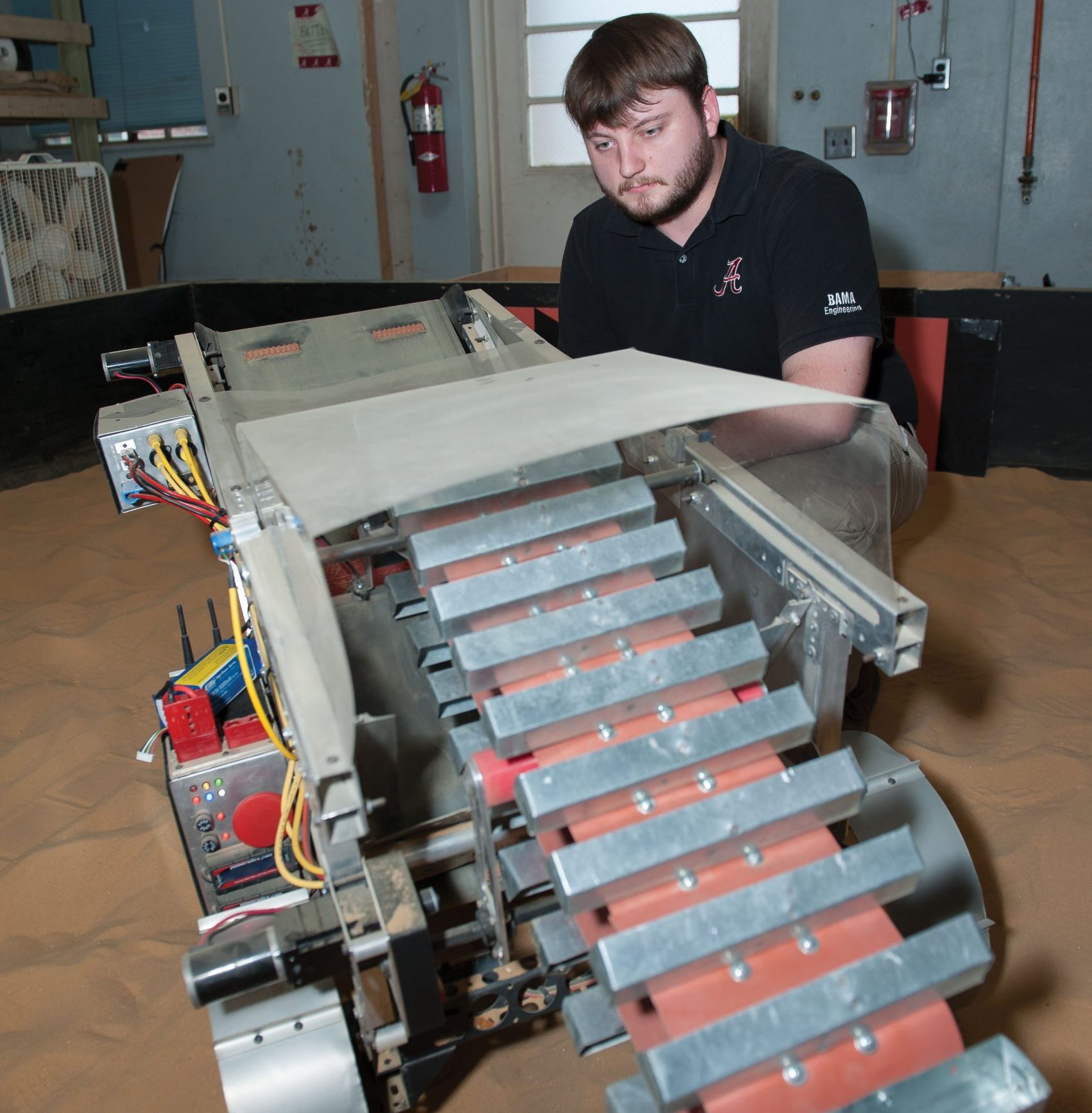

But the team actually got off to a meager start in 2009. Back then the team only had five members when the competition finally rolled around in the spring of 2010. The team was called Alabama Lunabotics at the time, since the competition focused specifically on mining lunar soil. The competition required the team to build a robot capable of navigating through and excavating at least 10 kilograms of simulated lunar regolith — a layer of loose material that covers a solid rock — within two competition runs of 10 minutes through an obstacle course. That year, the team finished sixth.

“That team was woefully undermanned and lacked significant experience building robots in general and, more specifically, had no experience with how robots would handle the simulated lunar soil in which the competition was held,” Ricks said. “However, the energy and enthusiasm of the students overcame the team’s weaknesses, and they laid the foundation for the organization we now have in place.”

After that first year, the size of the team grew, and it attracted students from across the College. With growth, the quality of the designs improved.

At the 2011 competition, competing against 50 teams from universities around the country, the UA team finished fourth. Each year students improved the robot, and each year their competition score reflected their efforts.

Just as the team has changed, the competition itself has changed a lot, too, with the general goal of navigating the terrain and excavating the regolith becoming more difficult to accomplish each year as new and more difficult requirements for the robot are added to the competition. Soon the competition evolved to encompass broader operations on planets and asteroids, and the team accordingly changed its name to Alabama Astrobotics.

So far, the team has managed to remain a step ahead by mastering concepts like autonomy and adjusting the size and capabilities of the robot to improve its mass and speed. For 2015, the team cut more than 20 kilograms from the mass of the 2014 robot to create one of the lightest robots in the competition.

For autonomy, Alabama Astrobotics is the only team to use lidar sensors on the robot. Lidar is used to detect a physical target placed in the arena, making it possible to calculate the robot’s position within the arena. This technique resulted in positional accuracies of 2–3 inches.

“This consistent level of excellence is unmatched and stands testament to the hard work and dedication of our students.”

– Dr. Kenneth Ricks

As a result, the team’s first competition run this year was completed by the robot fully autonomously, the first robot in the contest’s history to complete a run with complicated autonomous programming that could be used by an actual NASA robot on another planet or asteroid, Ricks said.

“Our successes are the result of having talented, dedicated students who recognize the value of hard work and who are not afraid to put in the hours necessary to be successful, “ Ricks said. “Our students understand the commitment required, and they have demonstrated they are willing to do the work. And, while this is at a different level than football, make no mistake about it. Winning a national championship in anything is hard to do.”